What is the biggest 3D printer in the world? Well, it is a massive machine, capable of producing objects larger than a commercial automobile. There are a few different potential contenders for the world’s largest 3D printer, but one special one is taking focus in this article.

The University of Maine houses this beast of a 3D printer, and the intended purpose might surprise you. If you’ve been curious as to what an industrial 3D printer can truly do, then the researchers at UMaine certainly have some things to show you.

Simply put, this is a marvel of engineering. It holds a lot of potential for future use cases and might further the cause of more readily available natural resources for civilian and defense engineering.

Building the Biggest 3D Printer

The biggest 3D printer in the world is a special project undertaken by the Univerisity of Maine in conjunction with Ingersoll Machine Tools. It is a massive beast of a 3D printer, laying down filament on a 100-foot bed.

Now, this particular 3D printer wasn’t built for industrial or commercial applications. Instead, it serves as a launch pad for research into experimental engineering. Instead of being used for superfluous one-off projects, it is being used by UMaine to serve as a testbed for environmentally safe construction materials.

Most impressively, the 3D printer was used by UMaine to print a massive boat, dubbed 3Dirigo. This 72-hour process yielded a 25-foot vessel weighing 5,000 pounds.

Some Technical Specs

The 3D printer is a massive structure and utilizes a 100-foot bed for actually printing material. It is incredibly precise, allowing for tolerances within 6,000ths of an inch. It has a total cost of construction of $2.5 million and can extrude filament at a rate of 500 pounds an hour.

UMaine’s 3D printer is capable of creating massive objects. Theoretically, it can print an object up to 100 feet long, 22 feet wide, and 10 feet high.

Of course, it is restricted by the physical dimensions of its printing bed. However, when taken as a whole, it is a rather impressive machine for printing things like vehicles.

What It Is Used For

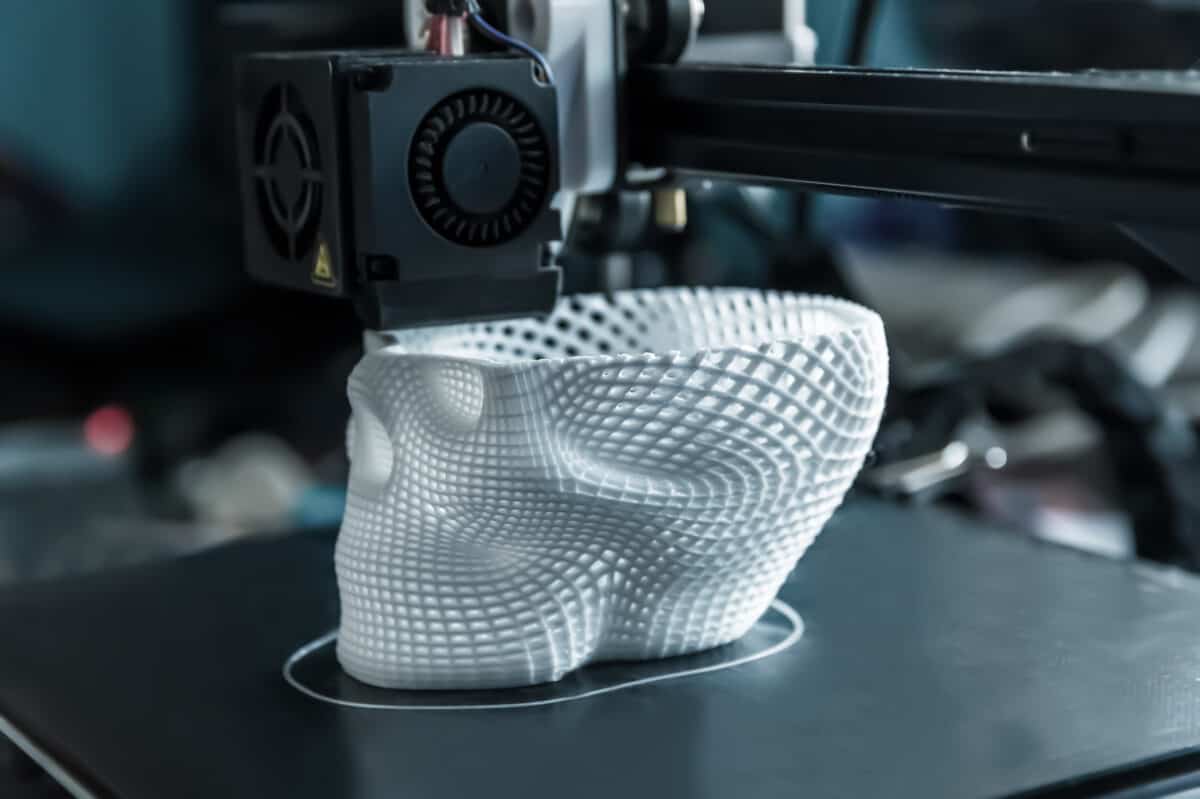

©Olga Ilina/Shutterstock.com

As previously mentioned, the UMaine 3D printer is being utilized for experimental materials for construction. One of the aims behind UMaine’s venture into the 3D printing space is to find more sustainable materials for future construction.

They’ve arrived at a combination of composite polymer resins and fibers taken from wood. These fibers, once pulped from one of Maine’s many trees, could be as strong as certain metals for construction. Of course, it is also recyclable.

While there are certain considerations to keep in mind when utilizing 3D printing, the biggest 3D printer looks to be leveraging environmentally sound practices.

The Materials Used for Printing

The world’s biggest 3D printer is the pet project of the Advanced Structures and Composites Center at the University of Maine. This is a massive undertaking with nearly 20 years of actual development and quite a bit to show for it.

Wood composites are nothing new in construction and engineering, as any builder or framer can attest. However, using these materials in place of metals is something wholly new. That’s just what the ASCC is planning to do.

The filament used by the 3D printer is derived from a fairly complex process. Lumber is processed in a traditional manner, as you might expect for other types of plywood. However, instead of crushing the lumber into basic pulp to be pressed into planks, it is instead shredded into strands.

These strands are then dried under an industrial conveyor drier before being run through a dehumidifying kiln to get the rest of the moisture out.

After that, the strands are blended with polymer resin, before being pressed into boards. This serves as the filament for the world’s biggest 3D printer. It is definitely one of the more fascinating aspects of this engineering marvel.

Wood as a Metal Replacement?

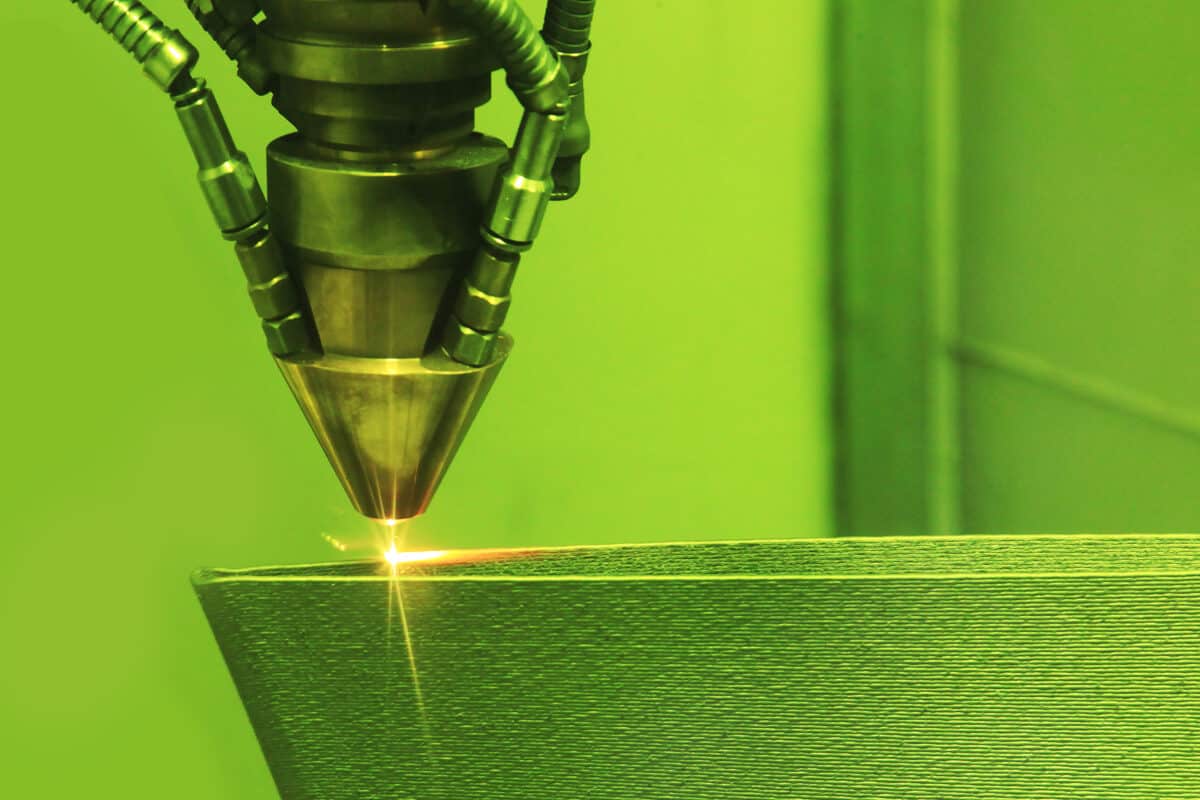

©sspopov/Shutterstock.com

Yes, you didn’t read that incorrectly. Strands of wood are being used as the main source for the filament used by the world’s biggest 3D printer.

Additive manufacturing typically doesn’t allow for structural integrity when constructing massive projects. Things like girders and beams still rely on traditional metal casting and forging to maintain strength and viability.

The hope behind the ASCC’s research and development is to create something that can readily create structurally sound materials in a matter of days that are custom fit for a job.

This sort of additive manufacturing can be seen with 3Dirigo, the fully functional boat the 3D printer was able to create in just 72 hours. Typical boats for most uses are made using a laborious process with fiberglass and wood composites in mold injection.

These materials aren’t recyclable, so they often end up in a handful once the boat is no longer seaworthy. 3Dirigo is fully recyclable. You can actually watch the printing process with the embedded video below.

Enter 3Dirigo

This article has made multiple mentions of 3Dirigo, so let’s formally introduce the vessel. 3Dirigo was printed in 2019 and serves as a proof-of-concept for the technology behind this sort of additive manufacturing.

It is 25 feet in length and weighs 5,000 pounds. It also comes with a multidirectional wave basin and wind machine. The resin composite used during the construction was only 50% polymer, with the rest being the experimental wood composite ASCC has been pioneering.

3Dirigo came fresh off the massive press ready for the sea. Once fitted with a motor it was ready to brave waters and performed admirably. It is certainly a massive departure from most industrial applications of 3D printing.

You’ll typically see additive metal printing, as is the case with the largest 3D metal printer in Rock Island Arsenal’s developments. 3Dirigo marks a new era of sorts of 3D printing. The industrial applications of this have yet to be fully realized.

One can only imagine what having multiple machines with this capability, working in unison could achieve. You could realistically assemble a fleet of vessels like this in a matter of weeks, rather than the time-consuming method used with injection molding currently.

Watching 3Dirigo’s Maiden Voyage

3Dirigo is seaworthy without finishing touches. For more information on the work with composites being done by UMaine and the ASCC, you can watch the informative video below.

The YouTube channel CompositesWorld gives a great overview of the work being done by UMaine toward additive manufacturing.

Closing Thoughts

The University of Maine has really achieved something with the world’s biggest 3D printer. While it might not be fully ready for prime time when it comes to industrial applications, it shows a path forward. As such, the world can only watch and wait as new ground is broken in manufacturing.